Digital and advanced analytics (DnA) are described by McKinsey as being the technologies that have the potential to transform manufacturing by enabling richer control over talent, data, technology and delivery. By using technology to enhance existing systems and processes, organizations can build a digital musculature that’s strong and agile enough to meet increasingly complex workplace safety and compliance requirements.

This is particularly relevant for industrial companies that operate within high-risk industries such as chemicals, oil and gas, and manufacturing – for these organizations, workplace safety isn’t a buzzword, it’s an imperative. A priority that’s a company-wide concern and inherent within the organization’s DNA. Ultimately, there can be no shortcuts when it comes to employee health and safety. This is why digital investment that leverages DnA can fundamentally re-imagine workplace safety management through the use of systems and solutions that are comprehensively integrated into core health and safety programs, and into business operations.

This integration of advanced technologies, including artificial intelligence (AI) prescriptive and predictive insights, allows for the digital-first organization to uplift its employees (increasing their capacity to undertake more complex tasks) and improve operations while simultaneously embedding safety at every touchpoint through the use of data and insights. Intelligent safety management solutions leverage constantly evolving technology and innovation to provide organizations with critical tools that prioritize hazard identification, risk mitigation, and accident prevention.

The DNA approach is one that weaves cross-organizational communication, cooperation, connected workers, intelligent insights, AI, and workplace safety into a coherent tapestry of efficiency and capability.

Centralized and intelligent worker safety

Centralized and intelligent worker safety

Health and safety management systems need to be capable of identifying, evaluating, analyzing, and controlling workplace safety and health hazards throughout the business, regardless of site location. This level of detail at scale ensures that the right people get the right insights at the right time and is one of the primary drivers of their ongoing evolution. With a digitally empowered system, the organization can exponentially increase awareness throughout the organization, which is of immense value to managers and decision-makers, while also ensuring ongoing compliance with safety regulations.

The value of these insights and controls can be felt across multiple levels within the business – from management commitment and accountability to employee responsibility. It will systematically improve the organization’s ability to detect hazards and control complex situations while providing essential data into incidents for analysis. The insights gleaned from this analysis can then be used to improve education and training, evaluate processes, potentially predict incidents or problematic areas, and refine site-wide processes and procedures.

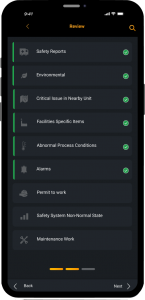

The GOARC effective workplace health and safety management system is designed to improve operational performance and workplace safety across multiple touchpoints, helping organizations realize the true value of digital and their inherent potential. The multi-level functionalities of the GOARC Safety 4.0 platform include:

Strategic organizational safety plans

GOARC’s comprehensive safety data management and risk assessment system provides important information about company processes. This level of detail empowers the organization to formulate a company safety structure that ensures ongoing responsibility and accountability within a detailed and relevant framework.

Considering that a company safety structure is essentially a safety roadmap that outlines protocols, responsibilities, and obligations across all levels of the company hierarchy, this is a powerful tool that has long-term relevance and defines the organization’s commitment to building a foundation of workplace safety excellence. It ensures that leaders select the most effective tools for defining methods and processes; implement systemic policies and actions; and establish measurable goals and performance indicators.

Workplace hazard assessment and refined policies and procedures

Holistic safety management systems focus on hazards from every perspective and are invaluable in overseeing process safety management and workers. By continuously assessing and evaluating operations, organizations can seamlessly and organically correct and prevent potentially dangerous situations.

An effective workplace safety system also helps to standardize company policies, enhance efficiencies, provide insights, and deliver risk management capabilities. These support operational processes and workplace safety for people and critical assets throughout the organization. It also ensures that another key element of safety management – risk control – is bolstered by richer data and input. Risk control relies on the diagnosis, review and evaluation of safety risks to prevent incidents, and to update and revise safety procedures. With the right technology, this provides critical and timely information about processes and workers for rapid decision making and issue resolution.

Finally, management systems also provide the organization with the infrastructure required to establish effective and reliable prevention and mitigation measures. It also allows for the company to determine the effectiveness of current safety measures and to implement relevant procedures that have long-term value.

Monitor and track performance and operations

Monitor and track performance and operations

Another essential part of an organization’s safety infrastructure is systemic cross-organizational monitoring and work supervision. This not only helps to identify hazards and apply controls but enforces safety policies and procedures while monitoring performance. With dynamic, process-related controls and monitoring, organizations can leverage GOARC’s ubiquity to facilitate preventative and corrective actions and achieve safety goals.

For high-risk industries, it is important to have coordinated and ongoing processes that safeguard the health and safety of workers, as well as to prevent environmental incidents. Having the ability to recognize risks in time and to receive critical updates or report potential issues is invaluable, especially when it comes to preventative safety measures, and this has the added advantage of ensuring all systems are kept up to the highest compliance standards.

Companies need the assurance that their monitoring capabilities are constantly updated and accessible through the management system. This provides decision-makers with new risk assessments, new assets, and processes, and supports the daily connected work environment – GOARC ticks every one of these boxes, and more…

Increased efficiency and productivity

Increased efficiency and productivity

Using digitally advanced and intelligent worker health and safety management software, organizations can gather and evaluate critical information that helps with decision making and accident prevention. This is key, particularly in high-risk industries – people are the most important assets and so workplace safety systems must prioritize them at every point. With GOARC, organizations benefit from increased safety as well as efficiency and productivity alongside measurable cost savings thanks to reduced safety incidents.

Enterprise-wide reporting and incident analysis

Perhaps one of the most invaluable layers within the workplace safety fabric is the ability to generate continuous improvements. This capability empowers the business, and its people by removing repeated incidents and issues from the table. Instead, with enhanced insights and analytics, the organization benefits from a centralized and integrated system that supports reporting, tracking, and the follow-up of worker or asset-related safety incidents. This is an efficient way to review the effectiveness of safety measures throughout the organization.

An added bonus is the GOARC single-source reporting capability that ensures management is always up to date and prepared for any incident or crisis management situation. This enables the identification and elimination of the root cause of accidents and near-miss incidents. The reality is that policy control and consistency can only be measured if all the safety information is accessible, organized in a central system, and provides insights that enable effective learning processes. With GOARC, organizations can review strengths, assess weaknesses and redefine processes using information that’s readily available and comes with relevant analysis.

Safety training

Safety training

Prioritizing safety isn’t just a matter of monitoring operations and implementing procedures, it’s about establishing clear safety objectives. This makes the personal commitment of employees a key component of safety training and education and forms the foundation of the organization’s safety culture. Employees need to know what workplace hazards they’re potentially exposed to, and how to respond in an emergency.

Leveraging effective safety management, workers – including supervisors and managers – receive the appropriate instruction and training alongside relevant feedback. This improves the overall competencies required for working safely and encourages the active participation of employees as they have an in-depth understanding of their individual safety obligations, site rules, and company safety policies overall. The feedback ensures that employees remain familiar with the right actions, understand risk levels, and recognise the control measures in place at every level of the organization. GOARC’s platform is designed to enable this level of comprehensive safety throughout the organization, regardless of division or operational site.

Workplace safety – proactive, preventive, and prioritized

A well-designed safety management system should sit at the heart of the organization. It’s features and processes ensure that health, industrial safety and personal safety are integrated throughout, and that the data and insights it provides are used to their full potential. With company-wide connectivity, ongoing communication, focused safety policies and system reporting, the GOARC system improves safety management while simultaneously reinforcing the right behaviors.

This systemic approach to controlling workplace safety and health hazards ensures full transparency, interconnected processes, and the real-time information delivered at speed throughout all levels of the organization. It allows for teams and leadership to identify high-risk situations and remain ahead of the problem, every step of the way. With GOARC, the organization gains a complete picture of the workplace at every level, in real time, and with insights that make all the difference for proactive and preventative workplace safety.

Enhancing your DNA with GOARC

Enhancing your DNA with GOARC

The GOARC platform is interconnected and connected throughout the organization ecosystem, delivering a real-time view of the plant’s operational reality with a radically more effective toolkit that can dynamically manage and visualize work activities. It connects workers and brings together disparate data from systems, sensors, and the worker-derived activities into a cohesive whole while providing the organization with meaningful and actionable insights. This includes the GOARC real-time visualization capabilities within the command centre, the GOARC Connected Worker system, and the interconnected data points and systems.

To address workplace safety issues and for a comprehensive solution to streamline and optimize your safety program, GOARC offers end-to-end, data-driven integrated solutions for health and safety management, enabling real-time protection of people and critical assets on a centralized, fully connected, visualized platform. Contact us to learn more about GOARC’s solutions.